In China, China National Heavy Duty Truck Group Co., Ltd. (Sinotruk) owns several factories and has the independent production capacity of engines and transmissions. Russian journalists made an on-site visit to the Sinotruk factory in Jinan, China, to explore the reasons behind the remarkable achievements of this enterprise in the global market. In 2023, the company sold 334,000 trucks, buses and special vehicles worldwide, accounting for 25.7% of the global market share.

Corporate Development History

China National Heavy Duty Truck Group Co., Ltd. (Sinotruk) was established in 1930, and in its early days, it mainly engaged in vehicle maintenance and production businesses. Before 1960, China did not have the independent production capacity of large trucks. At that time, it mainly produced light trucks or imitated foreign models. The Yellow River JN150 eight-ton truck became its first completely self-developed model, and this vehicle is displayed at the entrance of Sinotruk’s Laiwu factory. People familiar with automobiles may find that it has a similar appearance to the Skoda 706 RT, and this is not a coincidence. At that time, under the background of the country’s requirement for the research and development of domestic automobiles, the engineers of Sinotruk walked on the streets of Beijing to observe the passing vehicles. After selecting the appropriate model, they transported it to the site for in-depth research, and based on this, they developed the JN150. However, Sinotruk emphasized that only the cab appearance of the two vehicles is similar, and the internal cockpit and power system are all independently developed.

In 1983, China National Heavy Duty Truck Group Co., Ltd. (Sinotruk) initiated cooperation with foreign automotive giants and took the lead in assembling Steyr vehicles from Austria. This was not just licensed production; more importantly, it introduced advanced foreign production technologies, laying the foundation for Sinotruk’s entry into the international market. However, this process did not happen overnight, and the enterprise first needed to solidify its position in the domestic market.

At the beginning of the 21st century, Sinotruk attempted to cooperate with Volvo. Although the project was not successful, some of the achievements during the cooperation process became the research and development foundation for the Howo trucks. The Howo trucks were launched in 2005 and became popular as soon as they were introduced. The sales volume exceeded 10,000 units in that very year.

In 2007, China National Heavy Duty Truck Group changed its name to China National Heavy Duty Truck Group Co., Ltd. and was listed on the Hong Kong Stock Exchange. In 2013, the new generation of Sitrak trucks made their debut. In the seven years prior to that, Sitrak trucks were only sold in the domestic market and didn’t start to go global until 2020.

Today, the products of China National Heavy Duty Truck Group have been sold to 150 countries and regions, including Russia, the Middle East, Southeast Asia, the Near East, Latin America, Africa, Australia, and New Zealand, etc. However, due to the restrictions of agreements with partners, the company’s products face obstacles in entering the European and American markets.

Production Technology and Research and Development

By the end of 2024, China National Heavy Duty Truck Group Co., Ltd. (Sinotruk) had become a large-scale international enterprise, with six automotive production departments and eight special vehicle production departments under its umbrella. The total number of employees worldwide exceeded 30,000. The company has 27 factories in eight countries, among which there are five large-scale assembly plants, as well as multiple enterprises engaged in the production of auto parts and financial services in China.

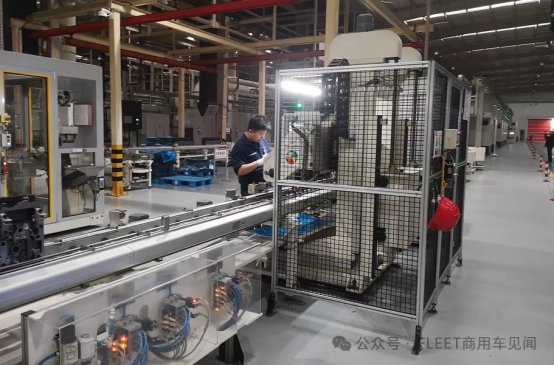

In Jinan, the reporters first visited the production factories of engines and transmissions. In this factory area covering an area of 504,000 square meters, 289 robots are responsible for the main production processes such as casting, welding, stamping, painting, and laser cutting, and a neural network system is in charge of monitoring the production process. The entire engine assembly workshop seems to be unmanned, but in fact, it is operating efficiently. According to the factory, it is usually in a “lights-out” state to save electricity, and the lights were turned on this time to facilitate the reporters’ visit. In the corner of the workshop, the reporters found three employees who were responsible for the final visual inspection of the engines. Sinotruk stated that artificial intelligence may miss some defects, so employees need to inspect all the engines that come off the production line during each shift. This factory produces approximately 700,000 engines annually.

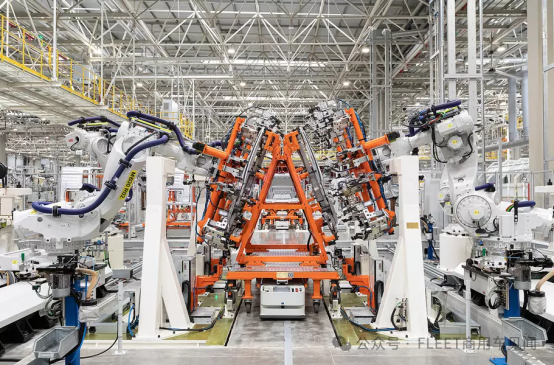

In another factory covering an area of 6,500 square meters, it is mainly responsible for the production of complete trucks. This modern factory took 10 months to build and cost $1.2 billion. Here, robots are also the main force in the production process. Components weighing up to 1 ton are transported by more than 400 automated guided vehicles (AGVs), and heavier components are handled by the manipulators on the roof or directly through the conveyor belt. The Sitrak trucks and Howo trucks have a similar appearance. The main difference is that the Sitrak trucks are equipped with more advanced electronic devices and the latest technologies, while the Howo trucks are relatively simpler in design and have a slightly lower price.

Sinotruk’s R & D center is dedicated to chassis and vehicle testing, conducting strict inspections on various performance indicators of vehicles, including material strength, operation of electronic devices, and exhaust emissions. In addition, the company is actively engaged in the research and development of alternative – fuel vehicles. During the visit, the reporters saw hybrid, electric, and hydrogen – fuel – cell trucks.

Employee Treatment and Work Environment

The monthly salary of factory employees is approximately 10,000 yuan (equivalent to about 137,000 Russian rubles at the current exchange rate). Although the salary is decent, the work requirements are strict. If there are production errors, employees will have their entire shift’s bonus deducted. New employees only have 5 days of annual leave, and for veteran employees, the maximum annual leave is no more than 20 days. Before starting work, employees are required to hand over their mobile phones to the safe. The working hours are from 9:00 to 17:00, and they work five days a week. In some factories, the working shift duration is 12 hours. The three employees responsible for the visual inspection of engines are prohibited from wearing headphones to listen to music during their work. They need to complete the inspection tasks alone in a quiet and monotonous environment.

Market layout in the Russian market

China National Heavy Duty Truck Group Co., Ltd. (Sinotruk) intends to achieve the local assembly of Sitrak and Howo trucks in Russia. Although the project details have not been announced yet, the company has stated that the Russian market is of great strategic significance to it. The company has already taken into account the needs of Russian vehicle owners and dealers, and has made more than 240 improvements to the vehicles.

In Russia, its customers include the retailer X5, Novatek, several logistics companies, and the Russian Post, etc. The Russian Post has just received a batch of natural gas-diesel hybrid tractors recently.